To consider an application for financing, fill out the form and send it to us by e-mail along with the project brief, or contact our experts

The introduction of modern technologies, especially in densely populated areas and large industrial enterprises, plays a key role in conserving resources, protecting the environment and improving human health.

The main objectives of the construction of wastewater treatment plants are as follows:

• Minimization of risks to public health.

• Reducing the impact of wastewater on the environment.

• Reducing the use of groundwater for economic purposes.

• Extension of the life of water bodies and aquifers.

• Ensuring compliance with environmental regulations and standards.

• Savings due to reuse of waste water.

Today, water purification is not only a solution to social and environmental problems.

It is a profitable business where it is important to achieve high efficiency and quick return on investment.

According to experts, the global water and wastewater treatment market in 2028 will exceed $ 250 billion, showing an average annual growth of 6-7%.

Modern wastewater treatment plants are designed according to the specific needs of the customer in order to achieve the specified quality indicators, which dictate the choice of technical solutions using various chemical, physical and biological methods.

We offer financing and construction services for drinking water treatment plants, reverse osmosis plants for seawater desalination and other facilities.

Our company with partners offers professional project management services in the field of water treatment, green energy production, waste recycling, environmental protection, and more.

Advanced solutions cover all stages of projects, from the construction of water pipelines to automation and control systems.

Wastewater treatment plant: structure and operating principle

Wastewater treatment plant is a set of engineering structures used to remove pollutants contained in wastewater from industrial enterprises and settlements.This also includes a number of ancillary facilities needed to power the facility and create an optimal working environment for servicing, controlling and monitoring technological processes.

The tasks of waste water treatment plants include the treatment and neutralization of sludge and the removal of other pollutants.

According to the type of wastewater treated, modern wastewater treatment plants are divided into:

• Municipal WWTPs, adapted for the treatment of a mixture of domestic and industrial wastewater with rain and melt water.

• Industrial wastewater treatment plants, which are used to treat wastewater from industrial processes. The technological profile and criteria for the effectiveness of wastewater treatment at these facilities generally differ from those that are taken into account when designing municipal wastewater treatment plants.

• Special purpose facilities that cannot be included in the system of typical urban and industrial WWTPs. This includes systems for the treatment of hospital wastewater, etc.

The construction of all wastewater treatment plants begins with careful planning and research, including determining the volume, chemical composition and properties of the water that the future facility will receive.

Along with the financial capabilities of the customer, this is a key factor in choosing specific technological solutions.

Wastewater treatment processes

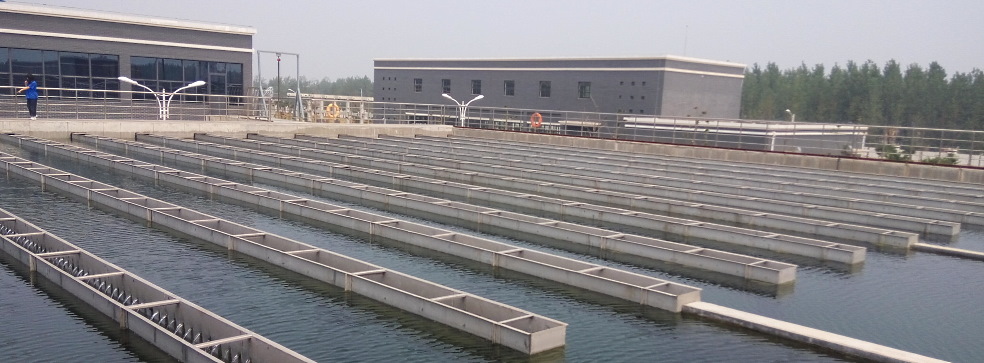

The modern technological chain of wastewater treatment plants includes a set of equipment for mechanical, chemical and biological wastewater treatment, as well as, in many cases, equipment for high-tech water recovery before reuse.First stage: mechanical (preliminary) treatment

Equipment for this stage performs simple mechanical operations (eg filtration and aeration) and enables highly efficient physical processes (sedimentation, flotation) to remove large particles of contaminants from wastewater.The main contaminants that are removed during the mechanical cleaning stage are:

• Large floating particles of solid waste.

• Granular particles (sand) with a size of 0.1 mm or more.

• Easily settling suspensions, the so-called primary sludge.

• Oils and fats that float to the surface.

Removal of other contaminants from wastewater at this stage of treatment is considered less important. It is also possible at this stage to treat the waste water by aeration or possibly chlorination.

For mechanical wastewater treatment, the following devices are used:

• Sand traps: vertical, horizontal.

• Sieves of various types, sizes and designs.

• Sedimentation tanks of various types.

Using modern mechanical treatment, in addition to separating large particles of garbage, sludge and sand from wastewater, enterprises can reduce the suspended solids content by 50-80%, as well as reduce BOD 5 and COD by 30-50% or more.

After separation from wastewater, the sludge is washed and compressed, collected in containers and sent to a landfill or special processing. The sand to be separated from the wastewater in the form of a sand slurry is washed and separated to remove organic matter.

Second stage: biological or chemical treatment

Biological wastewater treatment is based on the decomposition of pollutants in biological oxidation processes, which means the use of microorganisms.Almost all biological wastewater treatment processes are aerobic.

Wastewater must contain oxygen, which is consumed by bacteria and protozoa in their life processes, and therefore the oxygen concentration must be constantly maintained.

During the construction of modern wastewater treatment plants, engineering companies make extensive use of biological treatment equipment such as bioreactors.

This technological process takes place under artificial conditions that intensify natural biochemical processes.

The intensification of biological processes is achieved by maintaining an optimal amount of active mass of microorganisms and ensuring a constant supply of oxygen. Wastewater treatment is carried out in installations with activated sludge (biological reactors), the configuration of which depends on the type of wastewater and the substances removed from them.

During aerobic biodegradation, organic compounds are degraded by enzymes and then used to grow new microorganisms (increase biomass) and are oxidized to simple inorganic compounds such as carbon dioxide, water, nitrates, sulfates or phosphates. A feature of the technology of aerobic decomposition is the release of a significant amount of energy, which contributes to the growth of biomass and a faster course of the process.

Excess biomass is removed from the system in the form of sludge, which is sent for further processing.

Biological nitrogen removal includes the following processes:

• Ammonification.

• Nitrification under aerobic conditions.

• Denitrification under anaerobic conditions.

The selection of the most suitable process and equipment for the construction of wastewater treatment plants depends on the initial composition of the wastewater.

Wastewater chemical treatment technology

Chemical wastewater treatment consists in the addition of coagulants, iron compounds (for example, ferrous sulfate) or aluminum (for example, aluminum sulfate), and sometimes flocculants (anionic polymers).In some cases (at low pH) calcium compounds are added to the water.

The main purpose of chemical cleaning is additional phosphorus removal. It should be borne in mind that the addition of chemicals to wastewater will not only reduce the concentration of total phosphorus, but also significantly reduce the concentration of BOD5 and COD, the concentration of suspended solids and total nitrogen.

Depending on the order of adding the coagulant to the wastewater treatment process, there are three methods of chemical precipitation:

• Pre-sedimentation with the introduction of a coagulant into untreated wastewater (before primary sedimentation tanks). This is a typical process that requires rapid mixing, flocculation and settling. Pre-sedimentation can significantly reduce the load on biological reactors and reduce the cost of treatment.

• Simultaneous sedimentation. The introduction of the coagulant can be carried out directly into the biological reactor, as a result of which the phosphorus is precipitated during the biological wastewater treatment. At the same time, flocculation occurs and the resulting sludge is separated from the wastewater by sedimentation in secondary sedimentation tanks.

• Final sedimentation. Phosphorus is separated from wastewater after biological treatment in a separate process, including rapid mixing, flocculation and sedimentation (as separate operations). This method makes it possible to reduce the phosphorus concentration in the treated wastewater to a level below 0.1 g / m³ (in the case of filtration instead of sedimentation).

Stage three: water recovery for reuse

Highly efficient wastewater treatment processes are designed to ensure that the resulting water can be reused for domestic or industrial purposes.This is called water regeneration.

Water regeneration technologies complement existing wastewater treatment methods. They are based on processes well known in chemical engineering and commonly used in groundwater and surface water treatment. These are processes such as filtration, coagulation, adsorption and disinfection (chlorination, UV lamps).

Wastewater treatment plant construction: stages and considerations

Modern wastewater treatment plants are technically sophisticated structures that use numerous innovations, including biological treatment technologies and the reuse of gases generated during the work of biological degradation of sludge.The stages of construction of a wastewater treatment plant include:

• Exploration of the construction area.

• Preparation of technical documentation.

• Obtaining licenses and permits.

• Site preparation (earthworks).

• Construction of access roads.

• Civil construction work.

• Construction of canals and sand traps.

• Construction of a pumping station.

• Construction of a reactor for biological treatment.

• Construction of water sedimentation tanks.

• Introduction of technologies for gas reuse.

• Connecting the facility to the power grid.

• Setting up automation and control systems.

• Testing and commissioning.

Our company with extensive experience in the implementation of environmental projects, offers advanced financial and technical solutions for the construction of wastewater treatment plants.

We and our partners provide our clients with a full range of services, from research to operation and maintenance.

Selection of a site for construction

At the stage of site selection, the engineering company is looking for several places that are suitable for the construction of the facility.The best option is selected based on the results of geological, hydrological, topographic and social studies, as well as an assessment of the legal situation and negotiations with local residents.

When choosing a site, various economic, legal, social and technical factors, the current use of land and / or water bodies on the construction site and its surroundings are taken into account. For example, proximity to a wastewater source can reduce investment costs, but the direction of prevailing winds determines the potential impact of the facility on the local population.

When negotiating with local residents, it should be borne in mind that environmental projects of this kind create jobs and a temporary source of income in the immediate vicinity of the project area.

The availability of basic services for the operation of the facility, including electricity and access roads, is taken into account. Ideally, there should be medium voltage lines close to the site so that the site can be connected to the electricity grid at no extra cost.

Pre-investment research

The success of any environmental project depends on environmental, hydrological, geotechnical and other research.Based on the results of comprehensive research, the most suitable wastewater treatment technology is selected, which meets local requirements and the client's expectations.

It is necessary to analyze the sources of wastewater, the content of pollutants, the expected volume of wastewater entering the enterprise in different months, as well as determine the requirements for the quality of the treated water.

The sludge that forms after water treatment must meet stringent environmental standards. The composition of the sludge must ensure its final disposal without the risk of becoming corrosive, reactive, explosive, toxic, infectious or flammable.

The economic indicators of the enterprise are important for the approval of the project.

The expected service life of structures and equipment, their performance and consumption of electricity and other resources, the need for maintenance are taken into account.

Typically, the service life of wastewater treatment plants exceeds 20 years, and the cost of construction is estimated at tens of millions of euros. Investment projects of this scale require a professional approach at the stage of pre-investment research.

Construction site preparation

In the process of preparation, the land will be cleared and fenced in order to start digging canals and ditches later in accordance with the levels set in the project.In this regard, the volumes of soil excavated during earthworks will be stored on site for later use in order to level the area near the site, fill and compact uneven surfaces.

Particular attention is paid to safety and prevention of unauthorized access, since a significant amount of expensive machinery, equipment, construction materials and spare parts will be concentrated on the site.

One of the most time-consuming and costly preparation stages can be the construction of access roads, since in many cases sites for the construction of WWTPs are selected far from cities.

Purchase, delivery and installation of equipment

Together with our partners, we have long-standing contacts with the world's leading equipment manufacturers.This guarantees customers the purchase of the most advanced equipment on favorable terms.

Equipment for wastewater treatment plants includes:

• Installations for preliminary mechanical treatment of waste water.

• Various types of sand traps, which are highly efficient electromechanical equipment for removing sand and other fine particles.

• Sieves, including self-cleaning sieves, are used to remove coarse and fine solids of various sizes during pre-treatment of water.

• Augers, compactors and sand classifiers that separate sand and heavy deposits at the outlet of the sand traps.

• Rotary piston blowers as well as turbo blowers and highly efficient aeration equipment.

• Centrifuges for sludge thickening and dewatering.

• Recirculation equipment.

• Filter media, etc.

Civil engineering

During the construction of large wastewater treatment plants, a significant amount of general construction work is carried out related to the preparation of foundations, roads, canals, control buildings, fences and so on.A responsible general contractor with sufficient experience and technology in civil engineering will ensure high quality and timely execution of these works with minimal costs.

Disposal of construction waste

The construction of wastewater treatment plants involves the use of a large amount of metal, concrete and other materials.In addition, the preparation of the construction site produces large volumes of soil, sand and stone after digging channels.

Construction waste is of the following types:

• Stone, gravel, concrete and brick.

• Paper and cardboard: leftover bags and packaging.

• Waste wood: cut boards, pallets, etc.

• Metal waste: fittings, wire, old spare parts.

• Others: rags, organic matter, oil, etc.

Sorted and packaged construction waste should be sent for further processing in accordance with local requirements.

Waste management plans are often required to be submitted to local authorities during the permitting phase.

Benefits of WWTP construction under the EPC contract

Any large-scale environmental project requires the involvement of numerous equipment suppliers, subcontractors and highly specialized specialists from different fields.It is better to entrust the management of such projects to professionals.

EPC contracts are also known as turnkey contracts and represent the most popular project management approach. This abbreviation stands for Engineering, Procurement and Construction, and in this contractual model, many of the risks associated with the implementation of the project are borne by the general contractor.

In fact, the customer assigns to the contractor all responsibility for the project, including engineering design, procurement of equipment and materials, and timely completion of construction work. The contractor sets a fixed price that will not change even if the work requires additional costs. A fixed date for the commissioning of a plant is also important for customers.

The construction of waste water treatment plants under the EPC contract is gaining popularity due to the clear benefits for customers.

Benefits of EPC contracts

The first advantage is that the price is fixed and there are no unexpected costs.In other words, the client always knows how much he will have to invest in the project. An exception is the situation when changes to the project are made by the customer himself.

The second advantage of the EPC contract is that it clearly sets out the scope of work, technical requirements for the facility and the exact date for WWTP commissioning. The EPC contractor pays compensation in the event of work delays, which guarantees the fulfillment of the customer's own obligations.

The third advantage of this contractual model is that the customer does not have to control complex and multi-stage work with subcontractors. A small company does not need to open additional technical departments and hire staff, since project management is entrusted to professionals.

Finally, a large engineering company with international experience provides customers with the best technologies, personnel, materials and equipment necessary for the successful implementation of the project, and also solves any problems that may arise in the process.

Disadvantages of EPC contracts

While EPC contracts appear to be customer-friendly in general terms, this model may not be the best choice for small projects.First, the client must clearly state to the general contractor all of his needs and expectations. If this is not done, disagreements may arise during the construction of the wastewater treatment plant.

Another disadvantage is that EPC contracts are more expensive compared to EPCM, as the contractor takes on more responsibilities and risks.

In general, this contractual model is considered best for large scale and technically complex projects where the experience of the general contractor is key to success.

If you are interested in financing and construction of wastewater treatment plants or seawater desalination plants, please contact our specialists at any time.