To consider an application for financing, fill out the form and send it to us by e-mail along with the project brief, or contact our experts

The production of mineral fertilizers is becoming more and more in demand.

This chemical product is essential to ensure the food security of mankind.

Worldwide fertilizer consumption exceeds 200 million tons annually, showing an average annual growth rate of around 2%.

FAO projections indicate that the world's population will reach 9,100,000 by 2050.

Increasing the intensity of agriculture is a strategic challenge. In 1960, one hectare of agricultural land fed an average of 2 people, but by 2025 each hectare will have to provide enough food for 5 people.

Numerous American, European and Asian investors are interested in the construction of factories for the production of various types of mineral fertilizers, including phosphate, potash, nitrogen fertilizers, NPK fertilizers, etc.

The requirements for facilities of this profile are becoming more and more stringent. Rising fuel and electricity prices contribute to higher energy efficiency standards, and growing competition calls for better quality and lower product costs.

The company LBFL is ready to offer your business a full range of services, including long-term financing of a mineral fertilizer plant.

Mineral fertilizer production in Europe: past and future

Our ancestors began to cultivate the land tens of thousands of years ago.But the history of fertilizer production began when farmers discovered that some soils were no longer yielding acceptable crops after prolonged cultivation.

Application of manure to such areas restored soil fertility.

The emergence of the global mineral fertilizer industry began in the middle of the 19th century, when various types of fertilizers were commercialized. In 1842 Sir John Bennett Lowes of Great Britain patented the production of superphosphate from bones and natural phosphate deposits.

Complex NPK fertilizers and microfertilizers appeared much later.

As for potassium, the commercial use of mines for the extraction of this substance began in the 1860s in Stassfurt (Germany). The most important historical milestones were the synthesis of ammonia, patented in 1908 by Fritz Haber in Germany, and the subsequent implementation of this discovery on an industrial scale by Karl Bosch, who designed the first nitrogen fertilizer plant.

Since then, the use of nitrogen in agriculture has become very popular.

The production of solid NPK fertilizers began in 1950s, a step towards meeting the needs of large-scale agricultural production.

Section trends in the european fertilizer industry

European farmers must produce the highest quality food in huge quantities, minimizing environmental impact and conserving natural resources.These requirements are becoming increasingly difficult due to the limited availability of agricultural land.

To achieve agricultural goals, Europe needs close cooperation between farmers and industry.

Mineral and organic fertilizers developed in the EU are generally more suitable for the soil and climatic conditions of this region. The most outstanding of them both in terms of production volume and adaptation to the conditions of their use are nitrogen fertilizers, which are based on ammonium.

Complex NPK fertilizers are applied directly to the soil, so the plants absorb the necessary nutrients through the roots.

However, the conditions for the absorption of nutrients limit the use of fertilizers in terms of time and form.

With techniques such as fertigation and liquid fertilization, it is possible to more efficiently supply plants with nutrients, as well as manage their development and yield.

Liquid fertilizers are considered to be the most effective form, as they provide plants with all the nutrients they need at every stage of vegetative development. In addition, this form of fertilization dramatically reduces waste and environmental impact.

European fertilizer industry in numbers:

| Index | Value |

| Average annual sales, billion euros | 12,3 |

| Average annual investment in fertilizer production, billion euros | 1,2 |

| Number of employees involved in the sector, people | 82000 |

| Number of fertilizer production centers in the European Union | 120 |

| Average annual investment in R&D, million euros | 66 |

Currently the total European production of all types of fertilizers exceeds 17 million tons, of which over 12 million tons are nitrogen fertilizers.

This corresponds to 8% of the total world production of nitrogen fertilizers.

Mineral and organic fertilizers complements each other, since in conditions of high agricultural productivity, the addition of organic substances is important to prevent the deficiency of specific nutrients that limit the yield.

To meet the demand for sustainable food production without sacrificing productivity, both from an environmental and economic point of view, farmers are actively working with local industries.

The European fertilizer industry is developing in the following directions:

• Development of innovative products in close collaboration with leading scientific experts.

• Creation of fertilizers adapted to the needs of European crops, soil conditions and climate.

• Improvement of fertilization methods and their adaptation to the specific needs.

• Actively promoting professional advisory services to help farmers get the best results.

Fertilizer manufacturers are investing heavily in developing new technologies to reduce nutrient loss to the environment and more economical use of fertilizers.

Scientific activity is carried out in the following areas:

• Development of special fertilizers that adapt to the rate of absorption of nutrients by crops ("stabilized" coated fertilizers).

• Use of GPS tools and wireless sensors to timely monitor compliance with fertilization technologies in the fields.

Modern factories for the production of mineral fertilizers in Europe provide local agriculture with the main means of production, without which the development of this industry is impossible.

Mineral fertilizer plant design

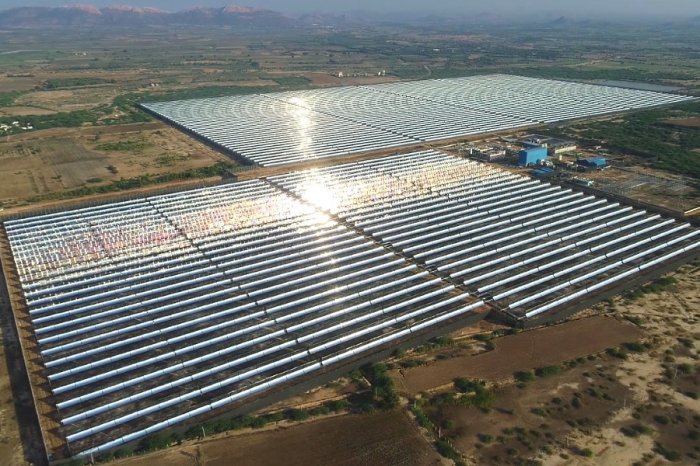

In this section, we provide general principles and stages of engineering design work.An example would be a liquid NPK fertilizer plant.

We with partners use advanced technologies and practical experience for financing and construction under the EPC contract.

Many successfully completed projects around the world are the best proof of our competence and reliability.

To find out more about our services and expertise, please contact our representatives. We will be happy to advise you and provide professional assistance at any stage of the project.

Mineral fertilizer market research

Detailed comprehensive market research to select the optimal plant capacity to ensure optimal return on investment, as well as determine many other project parameters.

This requires careful analysis of seven points:

• Sources and prices of raw materials.

• Evolution of the global and regional fertilizer market.

• Analysis and forecasting of changes in demand.

• Analysis and forecasting of supply.

• Existing production centers.

• Potential consumers.

• Fertilizer prices.

The decision to invest in the construction of a fertilizer plant cannot be viewed as accidental.

Today's highly competitive market requires caution and accurate calculation. Market research is a mandatory step in the pre-investment stage of the project, which guarantees future success and avoids significant capital losses even in the event of an unfavorable market situation.

Sources and prices of raw materials

In addition to water, the raw materials for the production of NPK fertilizers are phosphoric acid, nitric acid, nitric oxide, potassium nitrate, ammonium nitrate, potassium chloride, urea, monoammonium phosphate and other simple chemicals of inorganic origin.These raw materials can be purchased on the national market or abroad.

As a rule, the delivery of chemical raw materials within the country is carried out by heavy trucks and by rail, and imports in many cases involve the supply of large consignments of raw materials by sea.

At the pre-investment stage, numerous internal and external factors should be considered that can affect the cost and availability of various types of chemical raw materials.

For example, ammonia is the main raw material for the production of nitrogenous fertilizers. In recent years, increases in natural gas prices in developed countries such as Norway and Russia have contributed to a shift in nitrogen production to developing countries such as Algeria and Egypt.

Phosphorite is the main raw material used for the production of almost all phosphate products such as phosphoric acid and mono-ammonium phosphate.

Therefore, we need to compare the offers of the main countries with significant reserves of this raw material (USA, Russia, Tunisia, Israel).

For the production of potassium, factories use raw materials that are obtained from the most economical potash deposits in the sedimentary salt layers of ancient inland seas and salt lakes. Countries such as Israel and Jordan are known for importing significant industrial volumes of potassium chloride, potassium nitrate and potassium sulfate.

Marketing research involves comparing raw material prices. You should also consider shipping costs when ordering raw materials from different regions of the world.

Evolution of the global and regional fertilizer market

To increase the profitability of the supply of mineral fertilizers, the distance between the plant and the centers of consumption should be as small as possible. Delivering finished products over distances of many thousands of kilometers can make marketing difficult.It is necessary to carefully study the national and global demand for various types of products. Consumption of NPK fertilizers in recent years has demonstrated an increase of up to 15%, but some other types of fertilizers are going through hard times.

At this stage of research, all possible factors are taken into account that can affect global and regional demand in the future.

Analysis of changes in supply and demand

Using historical information on the demand for NPK fertilizers, we can make a forecast of the consumption of this product over the next 4-5 years, using the most accurate statistical methods.The technical arsenal of the engineering company includes the most advanced computer tools for analysis and forecasting, so our comprehensive approach ensures the safety of your investment.

An important indicator that reflects the economic feasibility of the deployment of production is the potential unmet demand. Based on the data obtained, we can make a forecast of the future development of the plant using several variables.

Existing fertilizer production centers

When conducting marketing research, specialists draw up a detailed report containing information about the centers of production of similar products — in this case, NPK fertilizers.The distance to the nearest factories is taken into account, since transportation costs and efforts to develop a dealer network depend on the distance to the center of production.

The main producers of NPK fertilizers as of 2017:

| Rating | Country | Annual production, million tons |

| 1 | Russian Federation | 8,4 |

| 2 | India | 3,8 |

| 3 | Indonesia | 3,3 |

| 4 | Vietnam | 3,3 |

| 5 | Poland | 1,3 |

| 6 | South Korea | 1,3 |

| 7 | Japan | 1,2 |

The international situation should be taken into account, including the activities of the main exporters of mineral fertilizers.

Currently, the leaders of this market are Russia, China, Canada, the United States, the Netherlands, Germany, etc.

Potential consumers of finished products

The list of potential consumers of NPK fertilizers is quite long.Fertilizer wholesalers with a strong presence in agricultural regions within the country or abroad play an important role.

Large consumers are cooperatives and holdings specializing in agricultural products. Finally, family farmers (small or medium-sized farms) also deserve attention, although this consumer group does not require significant amounts of fertilizer.

Mineral fertilizer prices

Liquid fertilizer prices depend on how the cost of chemical raw materials changes, world demand, production technology and other factors.If we are talking about liquid NPK fertilizer, the minimum price of the product is 150-200 euros per metric ton, showing an upward trend.

Purpose and justification of the investment project

The purpose of the investment project is the construction and commissioning of a plant for the production, storage and wholesale of liquid NPK fertilizers.Justification of the project includes the choice of the optimal location and specific technologies.

The growing population of the planet and the global demand for food are placing high demands on agriculture. On the other hand, agricultural land growth is limited as the jungle and rainforest that remains today are absolutely essential to maintain the climate.

Therefore, it is necessary to increase yields using productive but sustainable farming methods. Fertilizers must be used rationally, with maximum efficiency and respect for the environment.

Modernization of land cultivation systems make the use of mineral fertilizers in liquid form an increasingly popular and profitable solution.

The demand for new technologies in irrigation systems and new methods of fertilization require the use of liquid fertilizers that meet the needs of farmers.

When designing a fertilizer plant, it is advisable to select a plot of land in an agricultural area and with extensive use of drip irrigation.

Site selection for fertilizer plant construction

When choosing a site for construction, a general description of the industrial zone is drawn up.The report includes the layout, neighboring facilities, access roads, electricity supply, access to a water source, and topographic features of the area.

The area required for the construction of the main plant site must be at least 4000-5000 square meters.

Additional space is allocated for green areas, roads and parking lots for vehicles.

The final design of the fertilizer plant must comply with the legal requirements and regulations imposed by local authorities. In particular, the maximum height, building density, visual impact can be controlled.

Environmental and fire safety standards are always monitored.

When looking for an optimal location for the construction of an industrial enterprise, one of the most important factors is strong connection with neighboring areas and transport accessibility. We take into account the presence of major highways, railway stations, and airports.

Climatic, meteorological and topographic factors play an important role, such as temperatures, precipitation, soil conditions, natural vegetation density, and the likelihood of floods and other natural disasters which can affect production.

Social and economic factors are also taken into account, such as the attitude of the local community towards the construction of the plant, the availability of qualified labor and the possibility of settling employees in the vicinity of the plant.

Mineral fertilizer plant master plan

The choice of a specific chemical composition and form of the product (solution, supersaturated suspension and others) should determine the approach to drawing up a master plan, purchasing equipment and developing a technological chain.Typically, a liquid fertilizer plant consists of the following areas:

• Warehouses for storage of solid raw materials of closed or semi-open type, depending on the characteristics of raw materials. The warehouse area should have a free front for access to cargo vehicles and for loading and unloading operations.

• Warehouses for storage of liquid raw materials in tanks. Tanks must be located in specially equipped concrete bins to prevent possible leakage of chemical contaminants into the soil.

• Production workshops of the plant, where chemical raw materials are supplied from warehouses for dosing and mixing in reactors. From here, products must be transported to a separate warehouse for shipment to consumers.

• Administrative and auxiliary premises, including offices, a quality control laboratory, and a control room equipped with an automatic process control system.

• Warehouse for finished products, which, in the case of liquid NPK fertilizers production, consists of tanks enclosed in waterproof bunkers. A separate warehouse can be built to store containers with prepackaged products for shipment to consumers.

• Wastewater management system of the enterprise, as well as a warehouse for industrial waste generated as a result of the technological process.

Each fertilizer plant requires an individual approach to layout. The number, purpose and location of individual zones depends on the characteristics of the technological process, regulatory requirements and other factors.

Engineering design of machinery, equipment and structures

The most important equipment in this type of factories are storage tanks for chemical raw materials and finished products.Correctly selected and installed, they ensure a safe manufacturing process.

Fertilizer plants can use durable glass fiber reinforced polyester tanks.

Corrosion-resistant austenitic stainless steel tanks are also widely used.

They are produced with the addition of austenite-forming elements such as chromium, nickel, manganese and nitrogen.

Other industrial equipment includes:

• Loading bins.

• Conveyor belts.

• Reactors with stirrers.

• Steam boilers.

• Piping systems, etc.

The main equipment is connected by a piping system equipped with special filters, pumps and compressors.

The piping system consists of mechanical elements connected in such a way as to prevent unwanted leakage of the circulating fluid.

The main components of the pipeline system are the pipeline itself, reducers and control devices (control valves). These elements are susceptible to wear and tear during operation, so they require regular preventive maintenance and repair.

With significant hands-on experience in financing, construction and maintenance of fertilizer plants, we strive to ensure high reliability, durability and ease of use of equipment.

In particular, we give preference to universal and interchangeable components that simplify equipment maintenance.

Industrial process feasibility study

The experience of leading companies in the industry shows that transport is the most important factor in increasing the price of liquid fertilizers.In the case of the production of dry fertilizers, transport factor plays a lesser role due to the ease of transportation of products.

In any case, the distance from the plant to the consumers should be taken into account when preparing the feasibility study.

The estimated costs of fertilizer production consist of the purchase of chemical raw materials, water, heat energy, fuel, electricity, as well as staff salaries and other operating costs.

Financial and engineering services for the fertilizer industry

The company LBFL offers a range of professional services for the fertilizer industry in Europe and beyond.We and our partners financing and build plants, warehouses, tanks, production halls, offices, silos, foundations, industrial equipment and more.

Specialists help to modernize existing facilities, expand production capacity and replace obsolete equipment.

Together with our partners, we are fully responsible for the implementation of a mineral fertilizer plant project: due diligence, feasibility study, financing and business plan development, equipment procurement and delivery, general construction work, testing and commissioning.

Industrial construction is a highly specialized activity where experience in similar projects is critical.

The financing and engineering design of fertilizer plants requires strict adherence to modern industry standards.

Our multidisciplinary team works to best meet the needs of the client.

Please contact us at any time.

We will be happy to help you with your investment project.